CHOLINE CHLORIDE : Strong Animals – Natural Animal Health Products

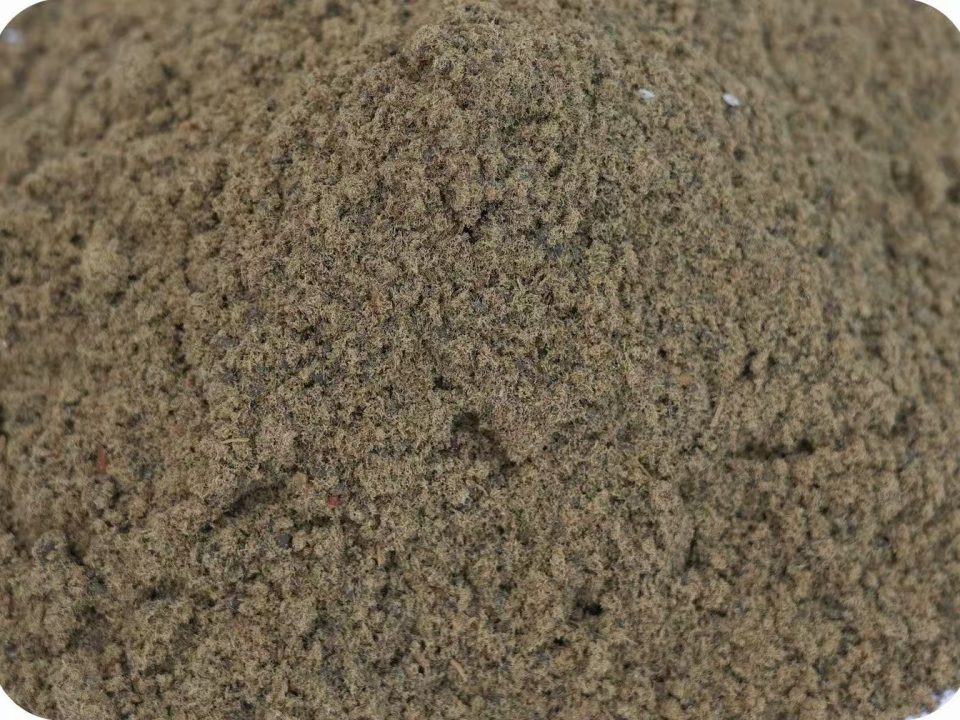

corn gluten meal (Feed grade)

October 9, 2017

CHOLINE CHLORIDE and Betaine for (Poultry feed, Swine feed, Ruminant feed,Aqua feed)

October 13, 2017Choline chloride is used as an important feed additive in animal species, especially chickens. Significant volumes of this compound are used in feed for poultry, swine, ruminant, aqua, pet, and horse. It is also known as vitamin B4 although it is required in a much higher level than vitamins. It helps to maintain cell membrane integrity and normal maturation of bone cartilages, thus preventing perosis.

Its other functions include prevention of abnormal fat accumulation, and as precursor of acetylcholine synthesis. Choline chloride is sometimes used as a supplement in human nutrition. Choline chloride is also effectively replacing potassium chloride in oil and gas industry, where it is used as a clay stabilizer. Choline chloride is environment friendly as a clay stabilizer as compared to potassium chloride.

Unintentional Quality Problems

Choline is a fairly simple molecule, yet important considerations go into making a high-quality product. Specific manufacturing considerations include:

• Ingredient quality – Carefully choosing the right ingredients is a very important step both for the production of liquid choline and for making dry choline from liquid. Ingredient selection is the single most important step for the prevention of dioxin problems with choline.

high-quality choline chloride products through:high-quality choline chloride products through:1. A wide product portfolio2. Total product chain control3. Moisture content below 2.5%(0.5% is typical)4. High choline chloride density5. The proprietary ability to spray choline chloride onto a carrier6. Dust free products due to particle size distribution7. No caking for good free flowing properties8. Very low residual total trimethylamines- ammonium (TMA) content. High TMA content results in a fish-like odor9. Dioxin free10. GMO free product availability11. Minimal undesirable substances (low values)12. Nutritional value in carrier13. Durable bags with polyethylene liner14. Short lead time15. Certifications: FAMI-Qs, HACCP, ISO 9002, 14001 and others

Quality Varies Among Choline Chloride Samples

| Choline content | TMA | Salts | |||||||

| sample# | Ccgrade | CC | CC | TMA | NH4 | Ca | K | Na | Mg |

| Test Method | 1C | Cl | IC | IC | IC | IC | IC | IC | |

| % | % | mg/kg | % | % | % | % | % | ||

| Specification | 59-61 | 59 -61 | <400 | <0.05 | <0.5 | <0.3 | <0.3 | <0.3 | |

| EU leg. 2002/32 | |||||||||

| C-01 | CC60 | 35.00 | 80.00 | 16 | |||||

| C-02 | CC60 | 50.20 | 59.20 | <25 | <0.05 | 0.80 | <0.3 | <0.3 | <0.3 |

| C-03 | CC60 | 52.10 | 60.10 | 65 | <0.05 | <0.3 | 0.41 | <0.3 | <0.3 |

| C-04 | CC60 | 52.50 | 59.90 | 85 | <0.05 | <0.3 | 0.46 | <0.3 | <0.3 |

| C-05 | CC60 | 28.50 | 64.60 | 2110 | <0.05 | 0.76 | 7.8 | 1.3 | <0.3 |

| C-06 | CC60 | 54.30 | 61.00 | 125 | <0.05 | 0.75 | 0.41 | <0.3 | <0.3 |

| C-07 | CC60 | 55.40 | 60.40 | 131 | <0.05 | 0.80 | 0.39 | <0.3 | <0.3 |

| C-08 | CC60 | 23.70 | 72.10 | <25 | 3.5-3.9 | 1.57 | <0.3 | <0.3 | <0.3 |

| C-09 | CC50 | 46.60 | 53.40 | 13450 | 0.29 | <0.3 | 0.41 | <0.3 | <0.3 |

| C-10 | CC50 | 45.70 | 52.90 | 13400 | 0.31 | <0.3 | 0.43 | <0.3 | <0.3 |

| C-11 | CC50 | 17.50 | 47.00 | 7675 | <0.05 | 0.45 | 0.31 | 5.4 | <0.3 |

| C-12 | CC50 (??) | 54.00 | 51.60 | 275 | <0.05 | <0.3 | 0.24 | <0.3 | <0.3 |

| C-13 | CC50 | 50.40 | 50.30 | 60 | <0.05 | 0.38 | 0.65 | <0.3 | <0.3 |

| C-14 | CC50 | 48.60 | 47.90 | <25 | 0.36 | <0.3 | <0.3 | <0.3 | <0.3 |

| C-15 | CC50 (??) | 58.60 | 58.90 | 50 | <0.05 | <0.3 | 2.37 | <0.3 | <0.3 |

| C-16 | CC50 | 19.30 | 52.60 | 3040 | 0.12 | 4.1 | 0.43 | 1.3 | <0.3 |

| C-17 | CC50 | 50.20 | 50.30 | 110 | <0.05 | <0.3 | 0.22 | <0.3 | <0.3 |

| C-18 | CC50 | 45.60 | 47.10 | <25 | <0.05 | <0.3 | 0.5 | <0.3 | <0.3 |

| C-19 | CC50 | 50.90 | 50.20 | 420 | 0.23 | <0.3 | <0.3 | <0.3 | <0.3 |

| C-20 | CC50 | 47.10 | 48.80 | 21 | <0.05 | <0.3 | 0.37 | <0.3 | <0.3 |

| C-21 | CC60 | 57.70 | 59.00 | 59 | <0.05 | <0.3 | <0.3 | <0.3 | <0.3 |

| C-22 | CC60 | 58.50 | 60.70 | 61 | <0.05 | <0.3 | <0.3 | <0.3 | <0.3 |

| C-23 | CC60 | 57.90 | 59.60 | <25 | nd | nd | nd | nd | nd |

| C-24 | CC60 | 54.40 | 59.40 | 615 | nd | nd | nd | nd | nd |

| C-25 | CC60 | 57.80 | 58.80 | <25 | nd | nd | nd | nd | nd |

| 0-03 | CC60 | 18.7 | 88.5 | 1745 | 4.6-4.1 | <0.3 | <0.3 | <0.3 | <0.3 |

.

Production conditions

-The synthesis of liquid choline chloride needs to be carefully controlled to produce a finished product that is clear choline chloride, low in odor and stable for long durations.

If the synthesis is not carefully controlled, a very “fishy” smelling choline product may result that is yellow in color and quite unstable during storage. In addition, it may not contain the proper amount of choline chloride.

– The drying of choline chloride to generate a dry product must be carefully controlled, as poor quality ingredients plus improper drying conditions can yield issues with dioxin formation. A poorly regulated dry choline production process can yield a product that is quite variable in finished choline content.